Gas Fusion

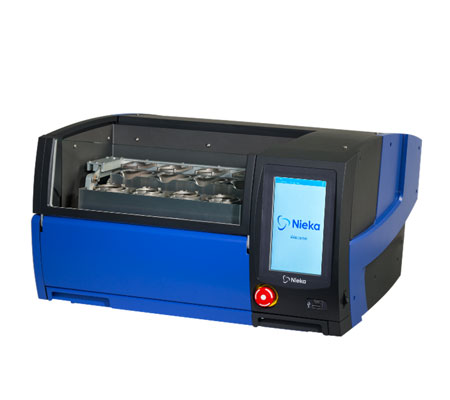

NIEKA G4

For the first time in a gas fluxer, the G-Series offers a reliable temperature monitoring of the fusion process. Nothing has been left aside, from perfect monitoring to perfect fusion: this will lead you to premium analytical results.

Built-in safety cabinet

You can see the entire fusion process and a locked door, that opens only when the cooling step is over, protects you. From the real-time flame monitoring to ultimate user safety, nothing has been left aside to provide you with the safest operation.

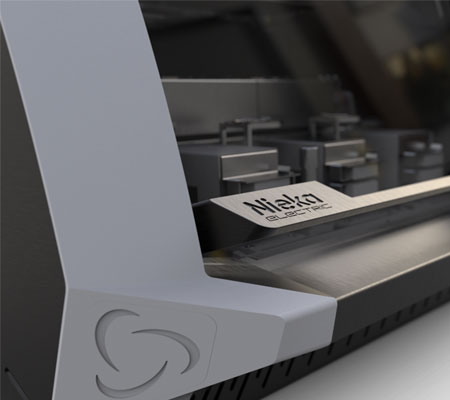

Sturdy mechanical systems

Nothing lasts forever but we’re getting pretty close with the G-Series: every component is oversized and built to outlast anything else in the industry.

Fusion temperature measurement

Our proprietary fusion enclosure allows the instrument to run on low energy while achieving the required high fusion temperature for difficult samples. For the first time on a gas fluxer, the G-Series reports an accurate temperature measurement of the fusion process.

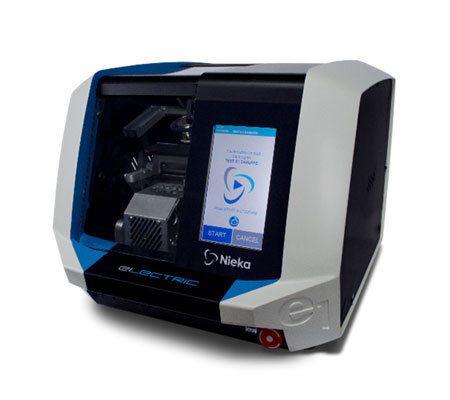

Huge built-in touchscreen

Use the built-in touchscreen display to edit your methods easily and follow the fusion process in real-time.

Dedicated mold heating

G-Series fluxers have separate burners for the molds. You can pre-heat any size of mold while reducing your overall fusion process time. The hybrid includes a snap-in module to prepare solutions for AA or ICP sample preparation.

Advanced self-monitoring

Thanks to its self-monitoring feature, the G-Series fluxer analyzes all instrument functionality and logs all the cycles so we can handle the maintenance schedule remotely. That's one more thing off your shoulders.

Features:

HIGH PRODUCTIVITY:

Produces 4 to 8 glass disks or solutions per cycle (up to 48 samples per hour).

AUTOMATED OPERATION:

Multilingual touchscreen controller with easy to access controls, import and export fusion method from USB or network, easy to follow fusion program execution through the instrument’s display or PC. All fusion parameters can be fully customized for optimal sample preparation.

MONITORING:

Temperature monitoring of the fusion process (patent pending), real-time monitoring through data management system.

EFFICIENCY AND REPEATABILITY:

Proprietary heating chambers (patent pending) allow a high thermal efficiency and higher fusion temperatures for difficult samples. Each chamber is well separated from the surroundings, allowing a perfect repeatability.

EASY INSTALLATION:

Only a low-pressure gas line and a standard electrical outlet are required. The G-Series runs on propane, any other liquid petroleum gas (LPG) or natural gas. No compressed air or oxygen is required.

OPTIONS:

The G-Series fluxers are available in 2 versions: 4 and 8 positions. Each unit can be delivered to make glass disks or solutions only or both (hybrid).

SAFETY:

Integrated locking safety door, real-time flame monitoring and automatic shut-off features, regulatory shutdown button.

CONNECTIVITY:

USB ports, TCP/IP Ethernet port.

REQUIREMENTS:

100-240V (50/60Hz) electrical supply, propane/ LPG (37 mbar - 0.5psi) or natural gas (20 mbar - 0.3 psi) line.